Water management is an essential aspect of the modern world and as the demand for water increases, it becomes crucial to adopt efficient and environmentally friendly techniques in India. Rubber dam technology emerges as a transformative solution with immense potential. Its versatility, efficiency, and environmental consciousness make it an ideal choice for optimizing water distribution, conserving precious resources, and mitigating the impacts of floods. By harnessing the power of rubber dams, we can embark on a path towards a more sustainable and resilient future, ensuring water security for generations to come.

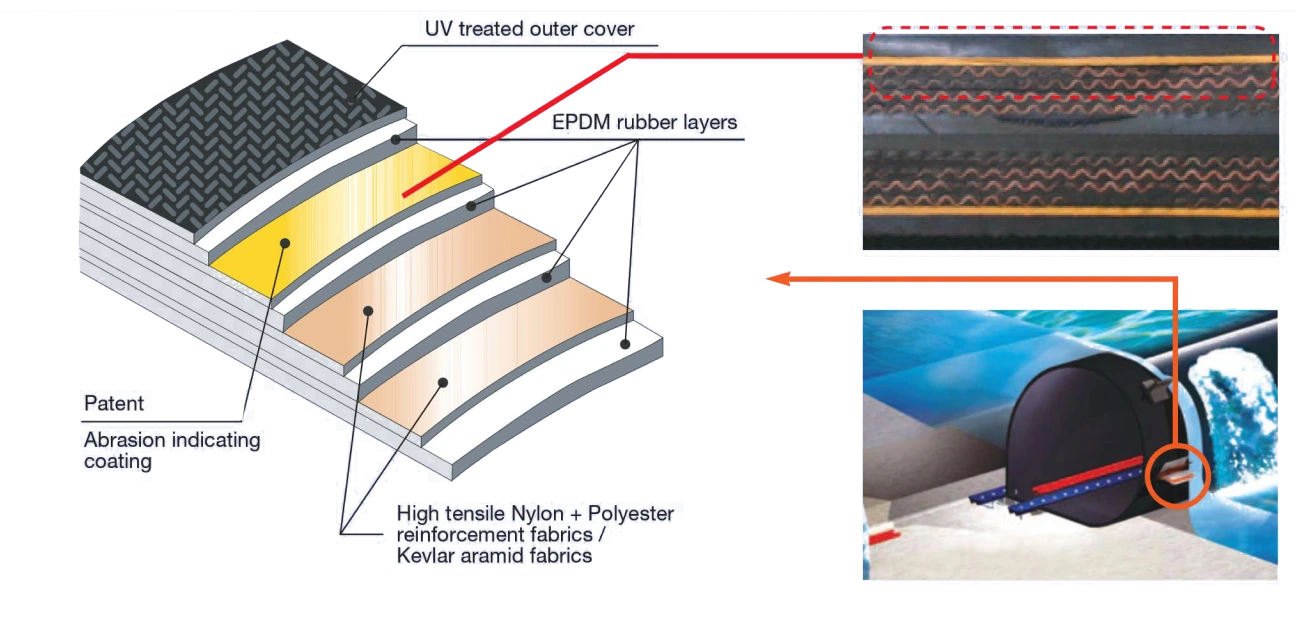

Rubber dams are hydraulic structures that control water in a more flexible manner than traditional water retention structures such as barrages, weirs, anicut and check dams. It is an air-powered flexible elliptical structure made up of high-quality rubberized material and attached to a strong concrete base. When inflated, they act as a weir and hold water; when deflated, they act as a flood mitigation mechanism and provide automatic sediment flushing. Around the world, more than 4500 inflatable rubber dams have been put into service.

Rubber dam technology offers several advantages in water management, making it a valuable tool for a wide range of applications. Some of the key advantages include:

It can assist in groundwater recharge by capturing and directing surface water into the ground. This process helps replenish aquifers and maintain groundwater levels.

Rubber dams are used as a diversion structure to create a small-scale hydropower facility. They can maintain a steady supply of water to turbines, enabling a reliable and efficient power generation system.’

Rubber dam technology offers a promising solution for increasing the storage capacity of existing dams or reservoirs. These flexible, inflatable barriers can be placed across the dam's spillway, creating an additional storage area behind them. They store excess water during periods pre and most mansoon and releasing it as needed during dry spellsand ensuring a more consistent water supply for downstream communities.

Rubber dams are used for river rejuvenation andin the creation of recreational water bodies such as lakes or ponds. These water bodies enhance the aesthetics and recreational value of an area.

Rubber dams can create temporary or seasonal water storage by impounding water in rivers or streams. This stored water can be used during dry periods, droughts, or for agricultural irrigation, providing a valuable source of water management and supply.

Rubber dams can be strategically placed along rivers and streams to create reservoirs for irrigation, domestic and industrial use. They provide steady supply of water for agricultural purposes, ensuring efficient water distribution and reducing water wastage.

Rubber dams have been used as part of environmental restoration projects. They can help create wetlands or enhance existing aquatic habitats by modifying the water flow and allowing for the establishment of diverse ecosystems.

Rubber dam are used to conserve water by creating reservoirs during pre and post mansoon flows and maintaining minimum flow levels in rivers for ecosystem support.

Our Rubber Dams are manufactured using top-grade materials, ensuring exceptional quality, durability, and performance.

Backed by years of experience in the industry, we deliver reliable Rubber Dam solutions tailored to meet your specific water management needs. Our in-house design and execution team closely monitors every project from inception to commissioning.

We are committed to environmental responsibility, offering eco-friendly Rubber Dam solutions that minimize ecological impact and support sustainable water management practices.

We understand that every project has unique requirements. Our team collaborates closely with you to provide customized Rubber Dam solutions that align perfectly with your specifications.

We offer comprehensive technical assistance throughout every phase of the project—from planning to installation—ensuring the successful implementation of your Rubber Dam system.