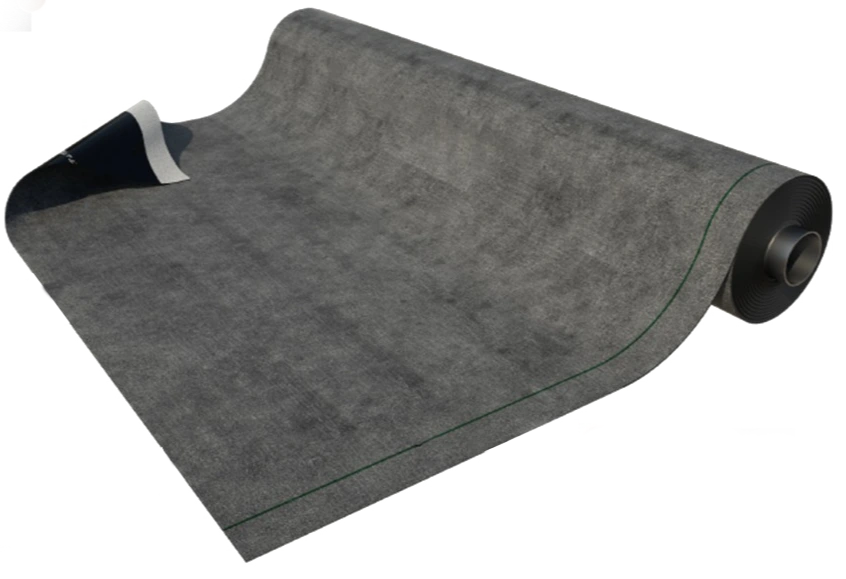

Bituminous Geo Membrane (BGM) is one of the most advanced, durable and innovative lining solutions of the geomembrane family used in water management systems. Bitumen was primarily used for waterproofing of irrigation canals in Mesopotamia, 4,000 years BC. Sections of these waterproofed canals are still in existence today. It is an high-quality waterproofing material because of its very low permeability of the order of 10^-14 m/s. It is manufactured by impregnating a non woven polyester geotextile with an elastomeric bitumen compound. In addition, the geomembrane is coated with sand on top to enhance UV resistance and an anti-root film at the bottom side to prevent the vegetation growth.BGM is commonly used for the lining of canals, power channels, reservoirs, ponds, landfills, mining applications and other hydraulic structures.

we offer a comprehensive range of Bituminous Geo Membrane Lining solutions that are specifically designed to address the challenges of water management with efficiency, reliability, and sustainability. Our top-quality Membranes are manufactured using the latest technologies and adhere to international standards, ensuring seamless waterproofing for a variety of applications.

Bituminous geomembrane (BGM) lining offers a wide range of applications across various industries due to its excellent properties, durability, and effectiveness in preventing water seepage and leakage. Some of the primary applications of bituminous geomembrane lining include:

BGM lining is employed in canals to minimize seepage and improve water distribution efficiency. It ensures that water reaches the intended areas without unnecessary loss.

Power channels play a critical role in conveying water for hydropower generation, and it requires perfect solution to avoid the water losses. BGM is an ideal lining solution because of its low permeability and ease of installation.

BGM lining is extensively used to line reservoirs, ponds, and lakes to prevent water seepage and ensure water containment. It acts as a protective barrier, reducing water loss and ensuring efficient water management.

Bituminous geomembrane (BGM) is widely used for dam waterproofing due to its excellent waterproofing properties and durability. When applied as a lining system, BGM provides an effective barrier to prevent water seepage through the dam structure, ensuring the safety and stability of the dam and its surroundings.

BGM lining is widely used in landfills and waste containment facilities to prevent the leaching of hazardous substances into into the soil and groundwater. It helps in maintaining the integrity of the landfill and protecting the environment from potential pollution.

BGM lining is utilized in various industrial applications, such as secondary containment for chemical storage facilities, wastewater treatment plants, and industrial ponds. It acts as a reliable barrier, preventing leaks and protecting surrounding areas from potential contamination.

BGM lining is employed in mining operations to line tailings ponds, heap leach pads, and storage facilities. It aids in containing potentially harmful substances and chemicals used in mining processes, thus minimizing the environmental impact.

BGM lining is suitable for fishponds, shrimp farms, and other aquaculture applications.It ensures water retention, prevents seepage, and maintains the required water quality for the aquatic species.

BGM lining is applied in wastewater treatment plants and ponds to prevent the seepage of treated or untreated wastewater into the surrounding soil and groundwater.

In the refurbishment of aging reservoirs, BGM lining can be used to extend their lifespan and restore their water containment capabilities.

Our bituminous geo membrane linings are manufactured using top-grade materials, ensuring good quality and performance.

Backed by years of experience in the industry, we deliver reliable solutions tailored to meet your specific water management needs. We have inhouse design and execution team which monitor every project from start to commissioning.

We are committed to environmental responsibility, offering eco-friendly options that minimize ecological impact.

We understand that every project is unique. Our team works closely with you to provide customized solutions that align with your requirements.

We provide comprehensive technical assistance throughout the project, from planning to installation, ensuring successful outcomes.

For more details please visit www.axter.eu/coletanche